DU Rubber Vacuum Belt Filter

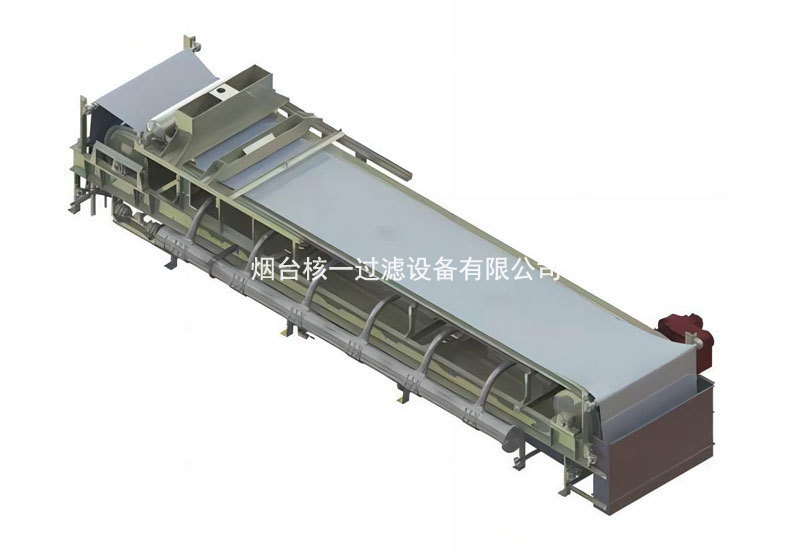

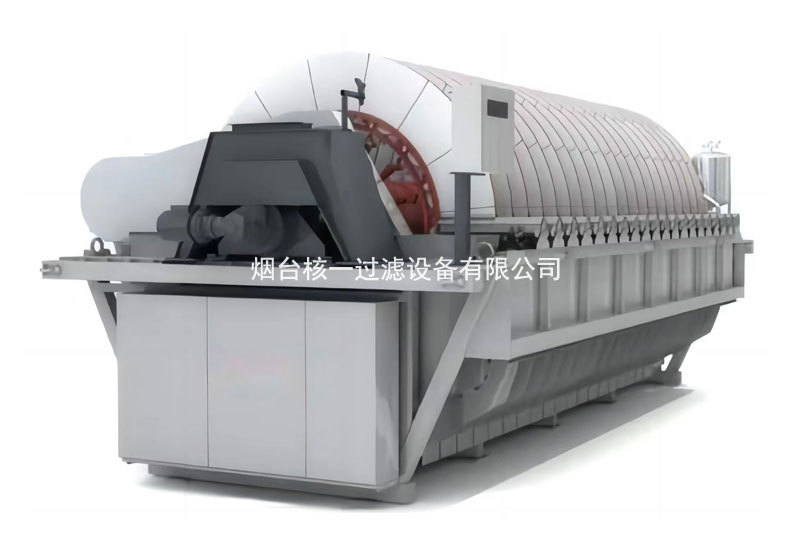

- Commodity name: DU Rubber Vacuum Belt Filter

- Product Description

-

Introduction to DU Equipment

The rubber belt vacuum filter is a high-efficiency separation equipment that uses filter cloth as a filter medium and relies on vacuum negative pressure to achieve solid-liquid separation. The equipment has simple structure, low production and operation costs, and is easy to maintain and operate. The production process is fully automatic, and the running speed, feed volume and washing water volume can be adjusted freely according to the production needs. After years of development, the technology of rubber belt vacuum filter has reached the international level and is widely used in electric power environmental protection, mining, chemical industry, metallurgy, paper making, food, pharmaceutical and coal industries.

Technical parameters (partial specifications)

DU Device Features

1. Adapt to a wide range of materials

Because of its unique structure, to adapt to a wide range of materials, especially for those vacuum drum filter can not be adsorbed, the solid particles are relatively large, the sedimentation rate is relatively fast slurry can be easily filtered, washed and dehydrated.

2. High filtration efficiency, filter cloth can be automatically washed and regenerated

(1), because the filter cloth constantly do rotary motion, each turn, you can complete the filter, washing, dehydration and filter cloth regeneration cycle, therefore, the filter cloth always keep fresh, always in the state of not being blocked, so the machine can not reduce the filtering capacity of the case of long-term continuous operation.

(2) The thickness of the filter cake layer is uniform and can be easily adjusted, so that the solid-liquid separation process is always in the best operating state.

(3) For materials with poor filtration performance and high viscosity, thin-layer rapid filtration can be achieved.

3, easy to adjust the air, strong adaptability

(1) By adjusting the speed of the filter belt and the thickness of the filter cake, the solid-liquid separation process can be optimized.

(2) The length of the filter section, washing section and dehydration section can be easily adjusted to make the solid-liquid separation process more in line with the requirements of the production process and enhance the ability to adapt to the material.

4, can achieve multiple reverse washing, washing water consumption is small

(1) According to the material characteristics and process requirements, one or more washing sections can be set.

(2), can be used countercurrent washing or washing operation, maximum saving washing water and improve the separation effect.

(3) According to the process needs, the washing water can be cold water or hot water to ensure the best washing effect.

5, can achieve fully automatic continuous operation

(1) The material is continuously input from the front end, and the filter cake is continuously discharged from the rear end.

(2) The filtrate is continuously discharged from the gas-liquid separator and enters the filtrate storage tank or the next process.

(3) The washing water can be combined with the filtrate or discharged separately.

(4), no special operation, greatly reduce the operating costs and can greatly improve productivity.

6. Good corrosion resistance

(1) Since the filter belt is made of corrosion-resistant materials (rubber, polyvinyl chloride, stainless steel, etc.), it can achieve better corrosion resistance.

(2), vacuum box, gas-liquid separator can be made of stainless steel, titanium and non-metallic materials, can adapt to a variety of corrosive materials.

7. Low energy consumption

(1), the filter belt running speed is slow, the spindle speed is low, the power is small.

(2) The vacuum box and the filter belt are well sealed, with less air leakage and low vacuum pump power.

8, the use of DCS system, can achieve remote and centralized control

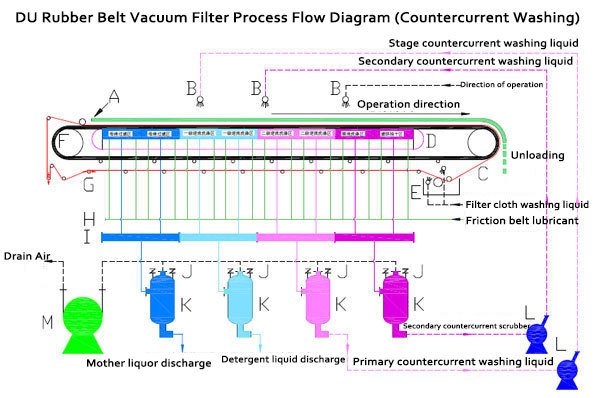

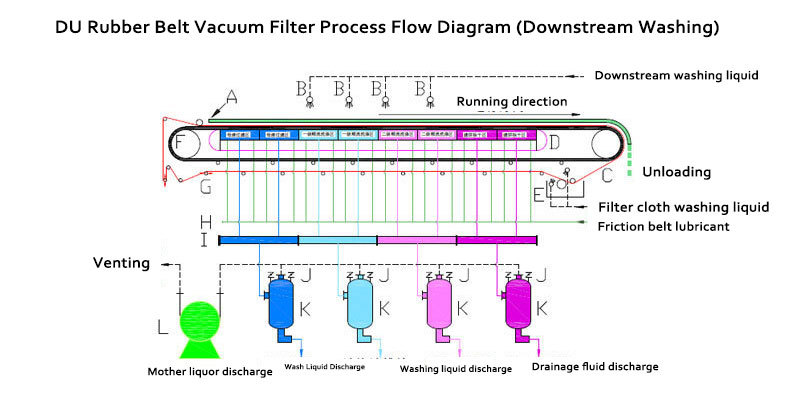

DU Basic Process

A. Slurry distributor B. Eluent distributor C. Filter cloth D. Friction belt E. Filter cloth cleaning device F. Rubber belt G, filter cloth correcting device H, filtrate main pipe I. Friction belt lubricating water pipe J. Vacuum/atmosphere switching valve K, automatic liquid discharge tank L. Countercurrent washing pump M. Vacuum pump

A. slurry distributor B. eluent distributor c. filter cloth d. friction belt e, filter cloth cleaning device f, rubber belt g. filter cloth correcting device h, filtrate main pipe I, friction belt lubricating water pipe j, vacuum/atmosphere switching valve k, automatic liquid discharge tank l. vacuum pump

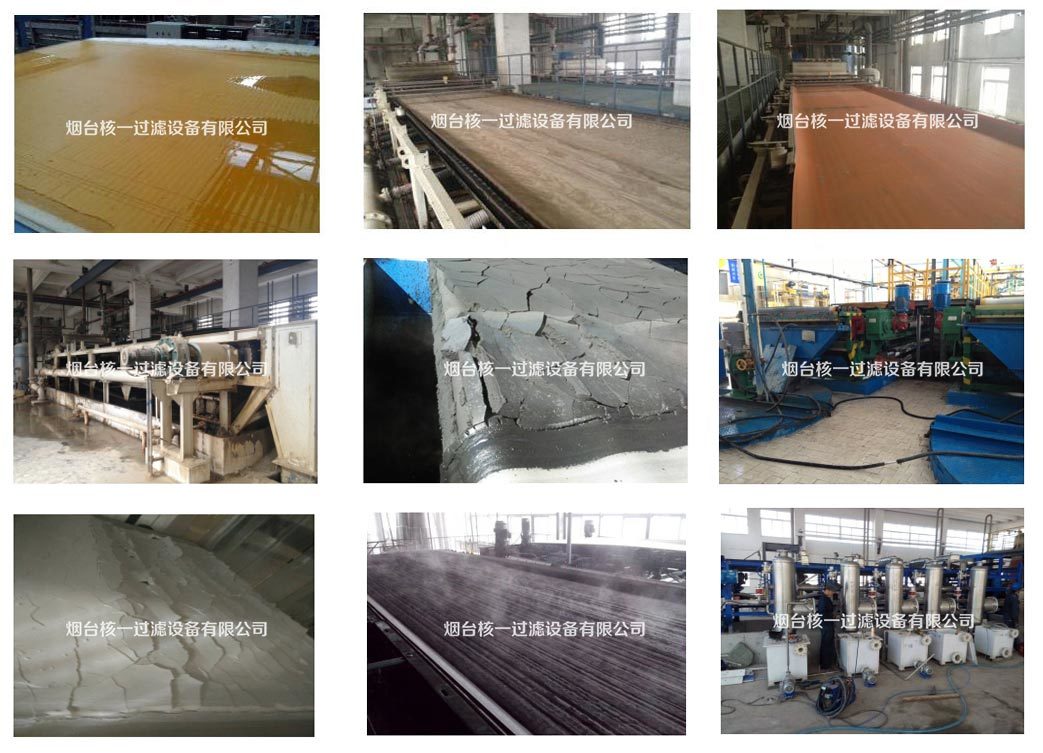

DU Application Site

Real scene of plant

Key words: