Automatic discharge centrifuge

- Commodity name: Automatic discharge centrifuge

- Product Description

-

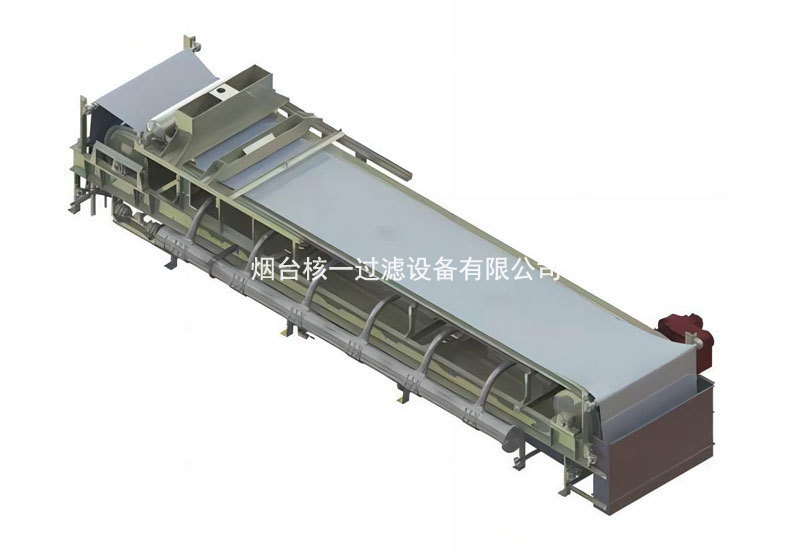

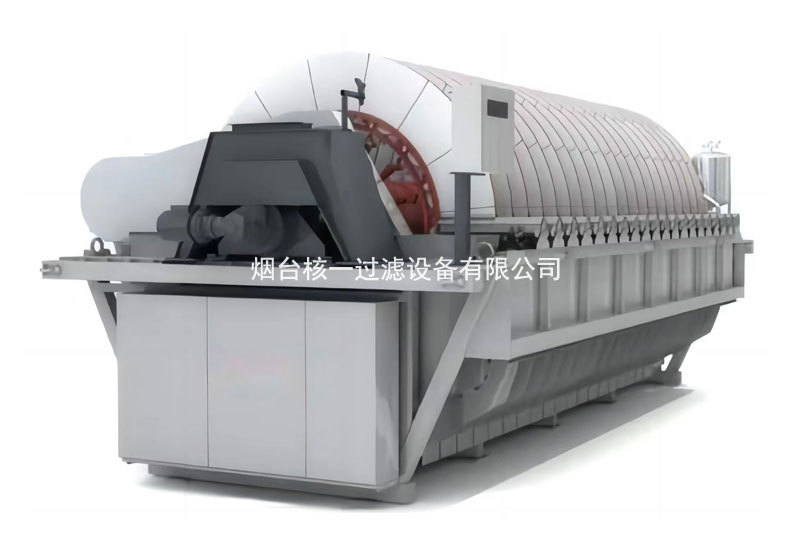

Equipment Introduction

HYLX series full-automatic centrifugal-discharge-diversion centrifuge is a kind of centrifugal filtration equipment with mature technology in our company. The centrifuge is a diversion type conical drum centrifuge, and its unique diversion device can adjust the residence time of the material in the centrifuge, so that the liquid content of the solid material is reduced to a minimum, and the material with solid particles greater than 30 ~ 40μm can achieve satisfactory results. The automatic continuous centrifugal discharge is realized, which is used as a filter centrifugal liquid removal. The products are widely used in electric power environmental protection, mining, chemical industry, metallurgy, paper making, food, pharmaceutical and coal industries.

At present, after market exploration, our company has finally determined that the following two specifications of products have stable performance, high degree of standardization, extremely low failure rate, and stronger interchangeability and adaptability of spare parts, which can effectively reduce customers' subsequent use costs.

Technical parameter table: (partial specifications)

Basic structure

● The suspension enters the centrifuge from the top under the action of gravity

● Centrifugal force throws the suspension to the cone filter

● Mother liquor passes through the filter screen

● Solid material is left inside the screen

● Solid materials move downward along the filter screen

● Due to the conical design of the diversion system

● Centrifugal force increases gradually.

● Solid material is discharged from the bottom

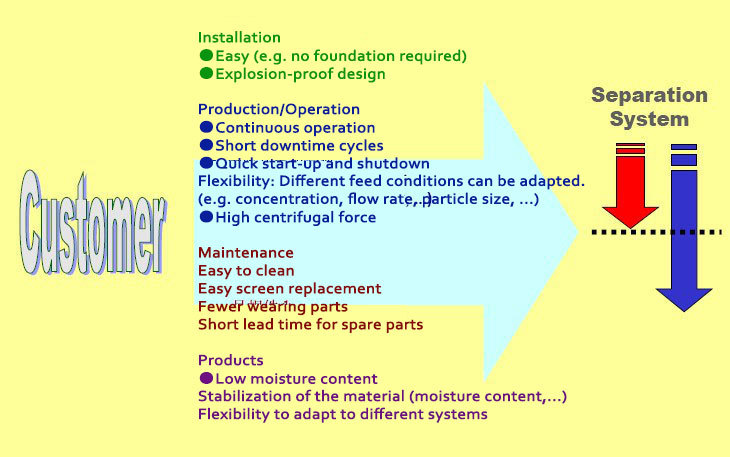

Equipment Features

Use of the site

Real scene of plant

Key words: