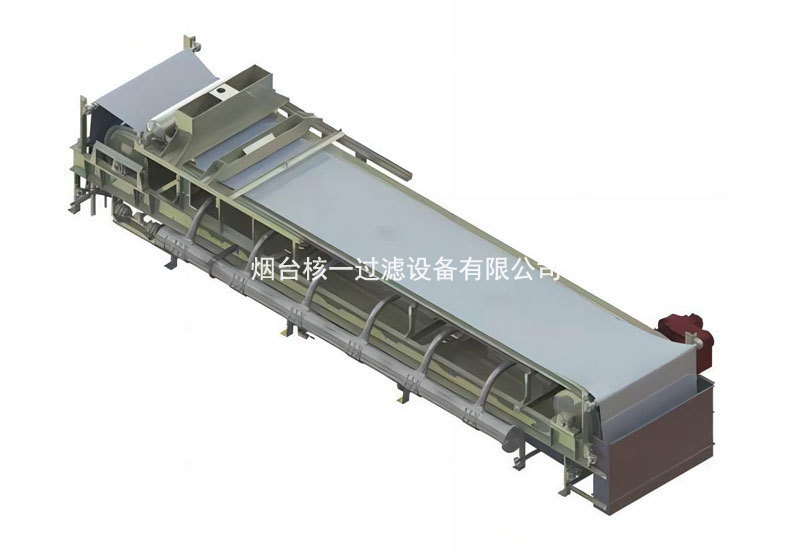

TC Ceramic Disc Vacuum Filter

- Commodity name: TC Ceramic Disc Vacuum Filter

- Product Description

-

Product Introduction

TM precision ceramic vacuum filter set electromechanical, microporous ceramics, ultrasonic technology as a whole, relying on vacuum suction and capillary action to achieve solid-liquid separation of new efficient, energy-saving filtration equipment. Widely used in mining, metallurgy, chemical industry, environmental protection and other industries.

Technical parameters

Product Features

★High vacuum degree (vacuum degree 0.09 ~ 0.098MPa), filter cake moisture is low.

★The filtrate contains <50ppm solids. Can be reused, reduce emissions.

★Compared with the traditional filter equipment, the energy consumption is saved by more than 90%, the energy consumption is low, and the operating cost is low.

★Compared with the traditional ceramic filter, the filter cake washing is increased, and it is suitable for the materials to be washed.

★PLC, microcomputer combined with automatic valve control, high degree of automation, reduce labor intensity.

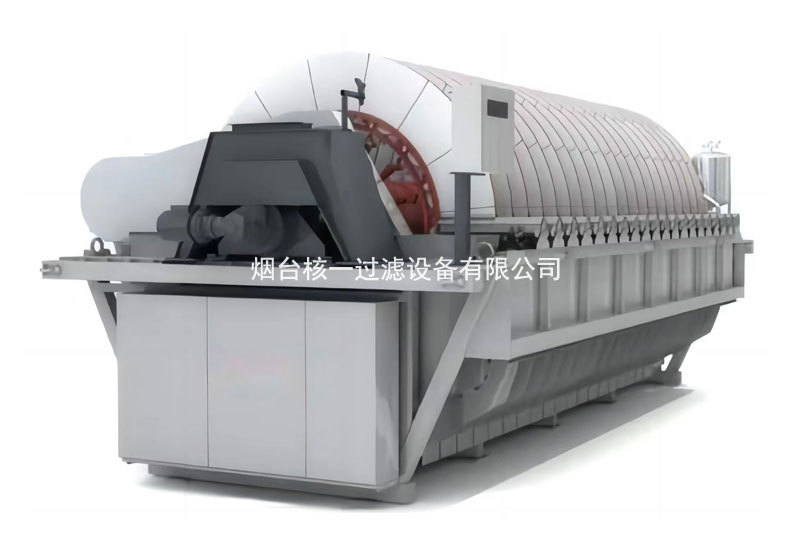

★Compact structure, small footprint, easy installation and maintenance.

★The mature drainage system can be used under any working conditions.

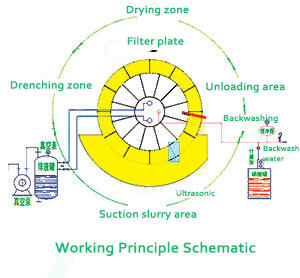

Working principle

Suction area: when working, the filter plate immersed in the slurry is combined with vacuum pressure under capillary action, and the surface is adsorbed into a layer of filter cake. The filtrate passes through the filter plate and enters the distribution valve to the drain tank.

Leaching zone: after the filter cake is transferred out of the slurry hopper, the filter cake is sprayed and washed.

Drying zone: The filter cake continues to be dewatered under the action of high vacuum forces.

Unloading area: in the case of no vacuum, the scraper automatically unloads.

Backwash: industrial water or filtrate through the distribution valve into the ceramic plate from the inside to the outside for cleaning. Clean the blocked micropores. After the ceramic plate is used for a cycle, the ultrasonic wave is mixed with low concentration acid to maintain the efficient use of the ceramic plate.

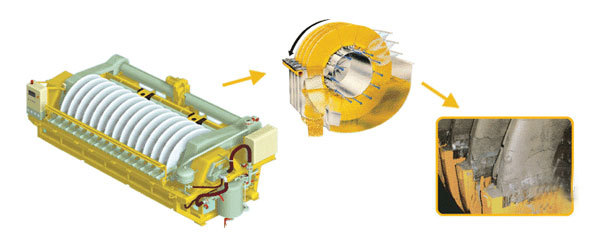

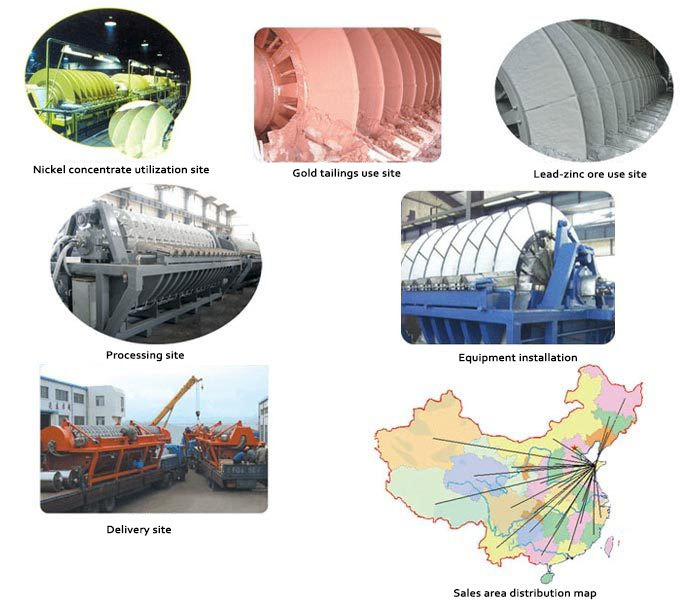

Ceramic filter effect drawing

Main components: filter plate, main engine, air-water mixed constant pressure backwashing system, control system

filter plate

Derived from international inorganic membrane technology.

1. Skeleton density, high film strength, wear resistance, pressure resistance and corrosion resistance.

Selection of fused white corundum by 500T hydraulic press gradient molding, 1430C overall sintering, pressure up to 8bar.

2. The opening rate is high, the production capacity is large, the filtration precision is high, the vacuum energy consumption is low.

The material is fine, the whole compound, does not use glue bonding, good water permeability, the opening rate of 92%; The 1800 mesh superfine white corundum pre-coating process is adopted, which has good capillary action and low vacuum energy consumption.

3. There are many regeneration methods and the service life is greatly extended.

It can be cleaned with high temperature and high pressure, organic solvents, etc., with good regeneration effect and long service life.

Control System

Using computer control system or touch screen combined with PLC control, feeding, filtering, cleaning, acid distribution, automatic control, stirring, spindle reducer adopts frequency conversion control, which can realize multi-machine operation, high degree of automation, simple and convenient operation, safe and reliable.

Gas-water mixed constant pressure backwashing system

Filtrate regeneration system adopts precision filter filtration, environmental protection and energy saving. The constant pressure water supply system is used for stable cleaning, which is safe and reliable. The use of ultrasonic combined with chemical cleaning agent joint cleaning ceramic plate, effectively ensure the efficient use of ceramic plate. Automatic acid distribution, reduce labor intensity and danger.

Scope of application

At present, it has been widely used in the dewatering of concentrates and tailings such as non-ferrous metals, rare metals, ferrous metals and non-metals in mines, the dewatering of oxides, electrolytic slag, leaching slag and slag in the chemical industry, and the treatment of waste acid from environmental sewage sludge. Material fineness from -200 to -450 mesh and a variety of ultra-fine materials.

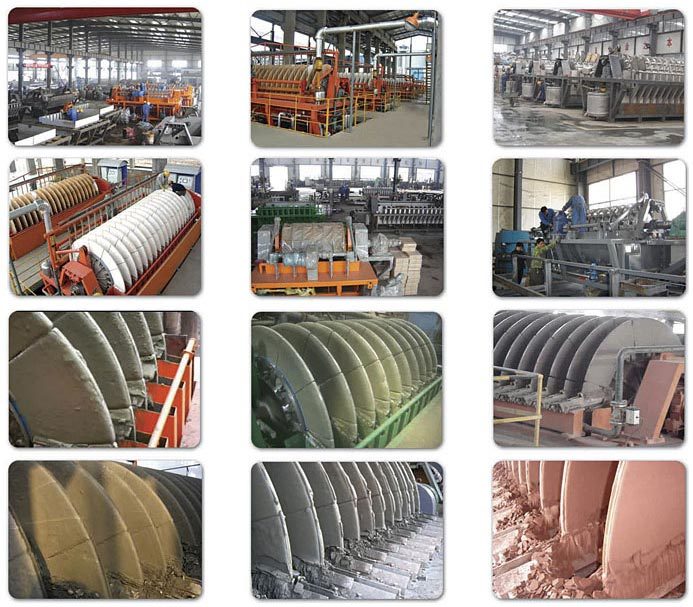

Real scene of plant

Key words: