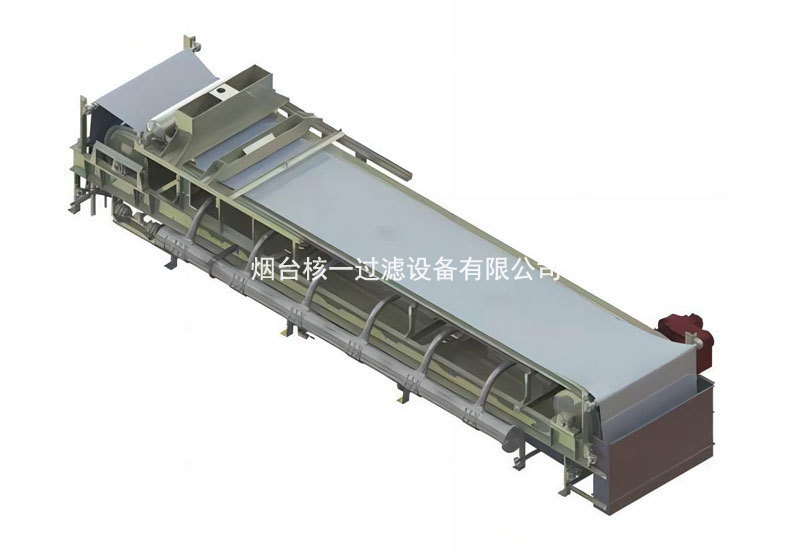

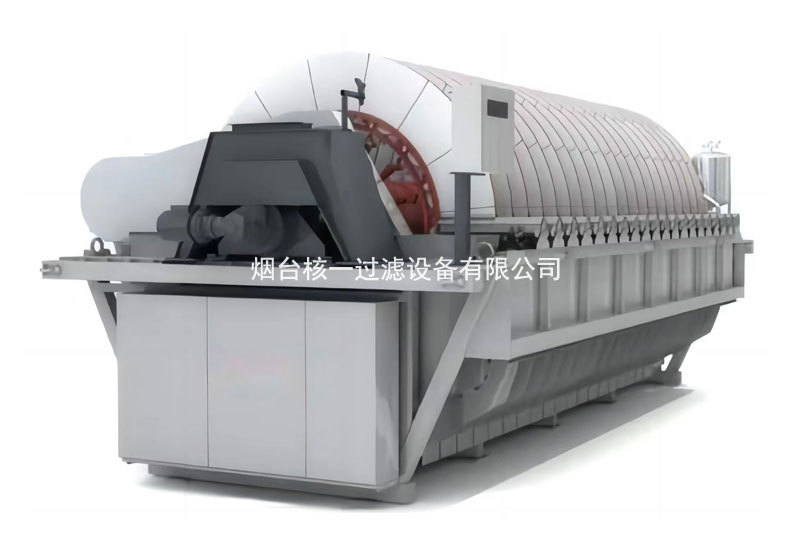

HVPF full-automatic vertical filter press

- Commodity name: HVPF full-automatic vertical filter press

- Product Description

-

Product overview

Nuclear one filtration HVPF vertical automatic filter press is a new type of solid-liquid separation equipment with high efficiency, energy saving and environmental protection developed by our company. The equipment uses the pressure of the pump, the gravity of the material and the squeezing effect of the rubber diaphragm to quickly filter the slurry through the filter cloth to achieve efficient solid-liquid separation.

HVPF filter press is a high-efficiency, energy-saving, high degree of automation of solid-liquid separation equipment. The equipment uses the pressure of the pump, high-pressure hot air and air pressure to form a pressure difference on both sides of the filter cloth to achieve efficient solid-liquid separation.

Technical parameters

Product Features

«Filter plate laminated structure, the use of guide devices, smooth operation;

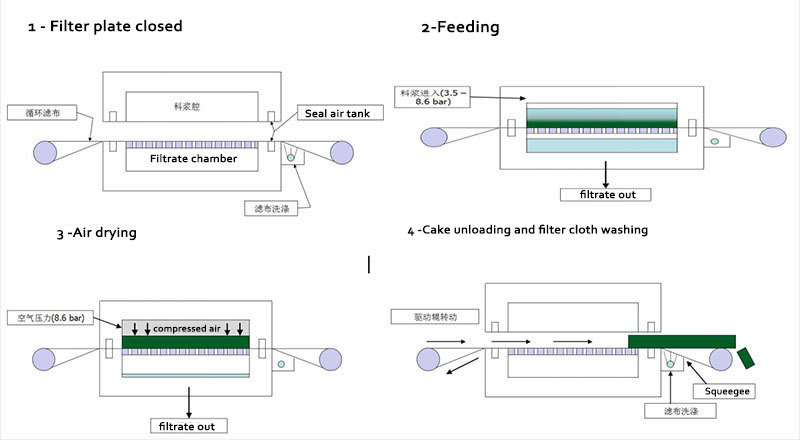

«Filtration, drying, unloading, filter cloth regeneration of the entire operation process can be completed continuously and automatically;

«filter cloth single layer independent circulation, high efficiency;

«High pressure hot air drying, low moisture content of filter cake;

«No diaphragm, no sealing strip design, low failure rate;

«Compact structure, small footprint;

Unilateral unloading, less supporting equipment;

«The plies can be disassembled independently and continue to be used for easy use.

Scope of application

Filter press is widely used in metallurgy, mining, chemical industry, coal chemical industry, titanium dioxide, papermaking, food, pharmaceutical and environmental protection and many other industries. It is the replacement product and technology of traditional filtration and pressure filtration equipment.

Working flow chart of filter press

Feature one, hydraulic cylinder structure

Four-cylinder synchronous guidance technology

The upper pressure plate of the equipment skillfully relies on hydraulic cylinders on four sides to drive the upper pressure plate to move up and down, and the hydraulic cylinders can achieve accurate synchronization and have good lubrication performance. The domestic four-column structure is avoided. Due to the poor lubrication performance and complex equipment structure caused by the use of separate four-column synchronization and the separation of hydraulic cylinder lifting, the defects of four-column guide column and pull-off lifting oil cylinder are easily stuck by external force, unreasonable design and high failure rate.

Feature two, hydraulic control technology

series-parallel synchronization technology

hydraulic cylinder synchronous control method:

1. Mechanical synchronization (rigid connection) (can not bear large load).

2. The shunt collecting valve controls synchronization, and the synchronization accuracy is 1%-2%.

3. Synchronous motor (or gear shunt) control synchronization, synchronization accuracy of 1.5-2.5%.

4. Throttle valve control synchronization (load balancing), poor synchronization accuracy

Feature three, automatic correction

Three-point positioning correction technology

The hydraulic cylinder is used to push the correction roller to deflect a certain angle to correct the offset of the filter belt, with high sensitivity; the filter cloth touches the proximity switches on both sides during operation, the proximity switch signal is transmitted to the control system, and the oil cylinder starts to act according to the preset setting. The cylinder only needs to move a small displacement can play a significant correction effect, the hydraulic cylinder adopts the domestic famous brand, the quality is reliable and stable. There are correction signal detectors on both sides of the filter cloth, and the filter cloth position alarm is used together to ensure the normal correction of the filter cloth.

Feature four, control system

Simple integrated control

The professional automatic production line has formed a professional supporting system from processing and manufacturing to product service. To provide customers with faster, better quality products and training services.

The whole system is completely controlled by PLC. The opening and closing of filter plate group, the operation of filter cloth, deviation and various process parameters are designed to be monitored. The working mode can be manually controlled and automatically controlled in each stage. The design has a stage timer, which can realize working cycle counting. The touch screen and PLC are used to realize digital communication, display the whole process flow, and have the ability to trace back the working parameters. Programmable controller and flexible program design are adopted, ensure that the system is reliable and accurate.

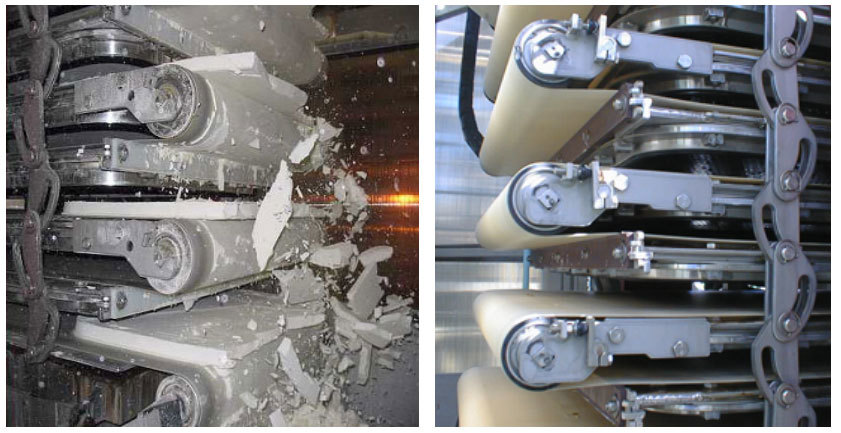

Features five, automatic discharge

Unloading without adhesion

The self-adjusting scraper unloading device can automatically adjust the angle of the scraper according to the position of the guide roller, so that the scraper and the filter cloth, the scraper and the guide roller are automatically attached to achieve the best unloading effect.

Features six, small footprint, simple structure, convenient enclosure

The tower filter press occupies a smaller area and has a lower height than the traditional filter press. Easy maintenance.

Each intermediate module includes a belt cleaning system. The belt cleaning system consists of a water receiving tray, a filtrate block, a spray pipe, a nozzle for cake unloading and a filter cloth washing. The cleaning is carried out simultaneously with no additional cycle time.

Real scene of plant

Key words: